|

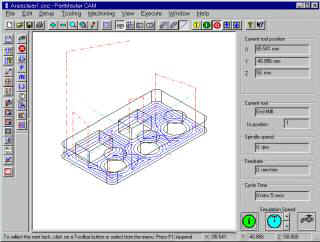

PartMaster Milling is a system designed to create complete prgrammes for

NC and CNC milling machines and machining centres. PartMaster Milling is

completely icon driven with easy to understand dialogs to input all

programme information - no programming language needs to be learned, all

required geometry can be automatically extracted from a PartMaster CAD

drawing or read directly from a DXF file. PartMaster Milling is ideal for

those new to CNC machining, whilst offering many advanced features for the

experience user.

Programme verification is made easy by fast, clean toolpath display in

top, side, front or isometric views

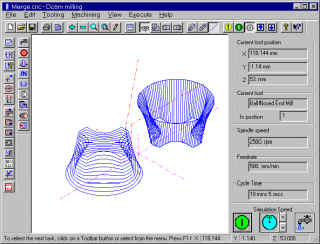

Example of the Merge command to create a

ruled surface between 2 contours at different Z heights

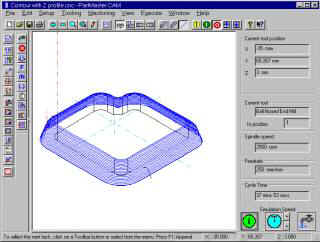

Example of Z-Profile for shapes with non

vertical sides

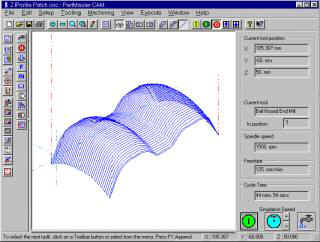

Example of surface patch defined by two

profiles

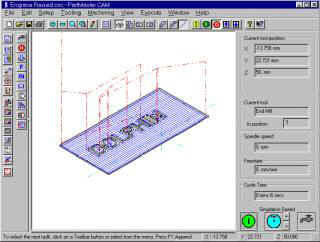

Example of raised lettering |

- Support for 2,

2.5 and 3 axis milling and rotary axes A and B.

- Tooling database.

- Display of

component and toolpath in Plan, Side and front Elevations and Isometric

Views.

- Display tool

centre-line, tool path envelope or full tool animation.

- Canned cycles for

milling, drilling, drilling, peck-drilling, deep-hole drilling, reaming,

boring, tapping and pocketing.

- Subroutines.

- Simplified 2D

contouring control with automatic generation of lead-in and run-off.

- Z axis profiling

which allows machining in the ZX & ZY planes.

- Tool offsetting

for ball-nose and square ended tools.

- Merge top and

bottom 2D contours to produce and machine aruled surface (square ended

tools).

- Automatic area

clearance of any contour with up to nine islands, with many machining

options.

- Engraving

facility that allows any text to be machined, with size, angle and

mirror image options, also radial text.

- Ramping with arc,

straight line or zig-zag approach

- Machining of

surface patches defined by two profiles.

- Ruled surfaces

defined by profile along line or turned around point

- Cycle time

estimates.

- Output to

virtually any machine tool controller, with the built-in post processor.

- Operator set-up

sheets which show tooling required and machining sequence.

Choose

from over 50 Post Processors including Fanuc, Heidenhain, Siemens, Rambo,

Hurco etc.

The end result ? reliable machine code that you can trust without

having to edit by hand |