|

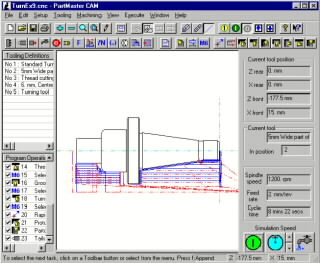

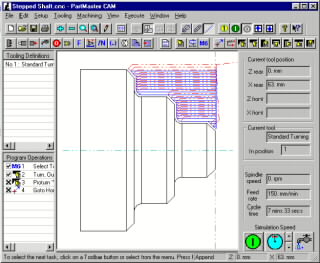

PartMaster Turning is designed to create complete programmes for NC and

CNC lathes and turning centres. PartMaster Turning is completely menu

driven so that no programming language needs to be learned, all required

geometry is automatically extracted from a PartMaster CAD drawing or

imported via a DXF interface.

PartMaster Turning is ideal for those new to CNC machine tools, whilst

offering many advanced features for the experienced user.

-

Canned cycles for facing and turning with automatic area clearance

between billet and finished profile, also facility for defining stock

such as a casting or forged blank.

-

Separate finishing allowance in Z and X.

-

Grooving cycles for face and diameter with options for lip and root

chamfers or fillets.

-

Part

surface programming.

-

Profile turning of any part of the profile in any direction

-

Constant surface speed control.

-

Gouge

free machining.

-

Cycle

time estimates.

-

Output to virtually any machine tool controller with the built-in post

processor.

-

Operator set-up sheets which show tooling required and machining

sequence.

|

-

Supports 2 axis lathes with either a rear or front turret, also lathes

with a cross slide.

-

Supports bar feeders, part catchers.

-

Tooling database.

-

Display tool center line or complete tool animation with stock removal

|